Promoting Environmental Conservation Activities

- HOME

- Sustainability

- Environment

- Promoting Environmental Conservation Activities

- Long Distance Conveyor Belts

that Contribute to Reducing

Environmental Impact - Response to Water Risks

- Greening Former Mine Sites and

Preventing Pollution - Conservation and Utilization

of Forest Resources

through Proper Management

of Company-owned Forests - Maintaining an Environmental

Management System

Long Distance Conveyor Belts that Contribute to Reducing Environmental Impact

The Torigatayama Quarry Complex features eleven long distance conveyor belts that transport limestone extracted from the mines a more than 23 km to the coastal ore processing plant. Using conveyor belts instead of trucks helps reduce CO2 emissions in transport and allows us to transport mineral resources with low environmental impact.

Five of the eleven conveyor belts are steeply sloped downhill, and we use the potential energy of the limestone they transport generates for other facilities effectively.

Additionally, to prevent dust and noise during ore transport, all above-ground sections are enclosed in soundproof galleries, and we conduct daily patrols and regular measurements and evaluations.

Response to Water Risks

The Group uses water mainly in the beneficiation process in the Mineral Resources business. Water resources are not only essential to sustain the Group's business, but are also very important to the residents of the communities in which we operate. Therefore, we are working to reduce our water consumption through efficient use and recycling of water resources and taking steps to meet our stated goal of preserving water quality.

We also use Aqueduct—a suite of tools developed by the World Resources Institute (WRI) to assess the status of water risks at production locations and laboratories—to identify areas with water risks, and recognize the Republic of Chile, where we develop and operate copper mines, as an area with particularly high water risks. In the future, we will conduct more detailed risk analysis and take steps to ascertain the amount of water used at each intake to ensure efficient use of water resources.

Recycling Water

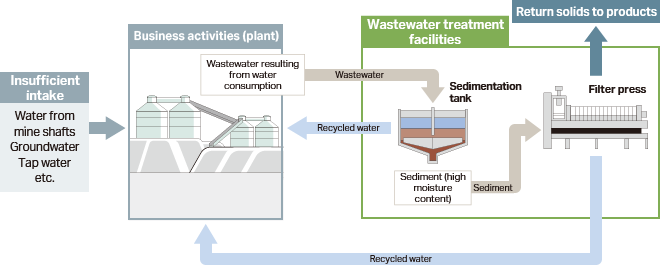

We strive to reduce both intake and wastewater by recycling water mainly in the Mineral Resources business. After using water in the beneficiation process to raise the grade of mined copper ore, in the washing of some limestone products, and toward other ends, we have wastewater mixed with solids, which we treat and recycle with wastewater treatment facilities.

Examples of water recycling in a limestone mine in Japan

Managing Tailings Dams

We produce copper concentrate at the ATACAMA KOZAN Mine in Chile. Tailings dams (tailings storage facilities) impound tailings—the slurry that remains after concentrate is removed from the ore during the production process—to allow the solids to separate from the water and settle to the bottom. From the start of operation in 2003 until 2020, the coarse grains of classified tailings were used as embankment materials, and the fine grains were allowed to settle on the insides of the dams. In 2020, we built a new tailings processing facility near the tailings dams and began using a method by which the tailings are allowed to settle after further dewatering than the old method. We recycle the water recovered from the dewatering process, which covers roughly 80% of the water needed for the production process, thereby reducing intake. Additionally, the new dewatered sediments are located downstream of the old sediments, which also has the effect of reinforcing the structure of the old tailings dams as they settle.

Tailings dam management involves daily water sprinkling to prevent dust, routine inspections, and scheduled surveying to ascertain storage capacity and conditions. We have also installed observation wells downstream to check for leakage, and regularly conduct water quality inspections.

Greening Former Mine Sites and Preventing Pollution

Mining development inevitably involves altering the environment, for example by removing trees from excavation areas. Decades pass between the development and closure of mines; we plant trees and vegetation in extraction areas and sedimentation sites after mining-related operations are complete in an effort to restore the environment and landscape. We also conduct patrols and inspections and perform the necessary maintenance at former mines throughout Japan to prevent pollution.

Greening results (consolidated)

| Unit | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|

| Tree planting | trees | 10,061 | 14,703 | 22,068 |

| Seed spraying | m2 | 47,667 | 83,057 | 9,800 |

Conservation and Utilization of Forest Resources through Proper Management of Company-owned Forests

As part of our CSR activities, we engage in sustainable forest management by planting trees on former mine sites and idle land. Among these efforts, we have obtained SGEC forest certification for our company-owned forest in Shiraoi, Hokkaido (area of roughly 1,200 ha), where we continue to foster healthy forest growth, conserve biodiversity, and replenish water sources.

To further reduce the CO₂ emissions of our Group, we promote forest growth through appropriate thinning and reforestation, aiming to obtain J-Credit certification for the CO₂ absorbed by these forests. Also, at other company-owned forests, we focus on maximizing the value of forest resources through proper conservation and management, with the goal of obtaining J-Credit certification.

Maintaining an Environmental Management System

We have obtained ISO 14001 certification at seven locations, including our Torigatayama Quarry Complex, the first mine in Japan to obtain certification that includes the scope of mining. By continuously maintaining the environmental management systems, we ensure that everyone at every location—from top executives to employees of affiliate companies—is working together to reduce environmental impact and prevent pollution.

ISO 14001 certified locations

- Nittetsu Mining Co., Ltd. Torigatayama Quarry Complex

- Nittetsu Mining Co., Ltd. Shiriya Quarry Complex

- Nittetsu Mining Co., Ltd. Ikura Quarry Complex

- Nittetsu Mining Co., Ltd. Higashi-shikagoe Quarry Complex

- Nittetsu Mining Co., Ltd. Oita Quarry Complex (including Tsukumi Limestone Co., Ltd., Tsukumi Cooperative Mining Co., Ltd.)

- Nittetsu Mining Co., Ltd. Tochigi Quarry Complex (including Kuzuu Limestone Aggregate Co., Ltd.)

- Nippon Ball Valve Co., Ltd.