Development of Functionalized Calcium Carbonate

Functionalized powder can be synthesized by combination of calcium carbonate and other fine particles.

Our original technique of particle morphology control and particle combination make it possible to synthesize functionalized calcium carbonate powder which has both advantages of calcium carbonate and other fine particles combined on the carbonate.

- The patterns of combinations are infinitely considered.

- Whiteness, Opacity, Dispersion, Oil absorption, Water absorption, Porousness, etc.

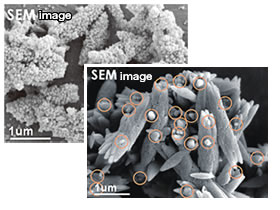

The fine particles, such as silica and titania, are uniformly combined on the surface of synthetic calcium carbonate with particle forms of spindle-shaped and columnar-shaped, etc. Moreover, spindle-shaped calcium carbonate can be coated onto a plate particle of kaolin. Incidentally, sepiolite can be combined with calcium carbonate particles.

The fine particles, such as silica and titania, are uniformly combined on the surface of synthetic calcium carbonate with particle forms of spindle-shaped and columnar-shaped, etc. Moreover, spindle-shaped calcium carbonate can be coated onto a plate particle of kaolin. Incidentally, sepiolite can be combined with calcium carbonate particles.

Calcium carbonate is synthesized with a carbon dioxide chemical reaction method, which the carbonate is precipitated by introduction of carbon dioxide gas into calcium hydroxide slurry. The shape and size of calcium carbonate can be controlled by adjusting the condition of its precipitation reaction. The combined particle can be obtained by an addition of the other fine particle to the reaction process of calcium carbonate mentioned above.

—Term—

- Kaolin

- Aluminum hydrated silicate mineral like a white scale. It's used for a paper making and the plastic use.

- Sepiolite

- Fibroid magnesium hydrated silicate mineral. It's used for building material and the insulator use.