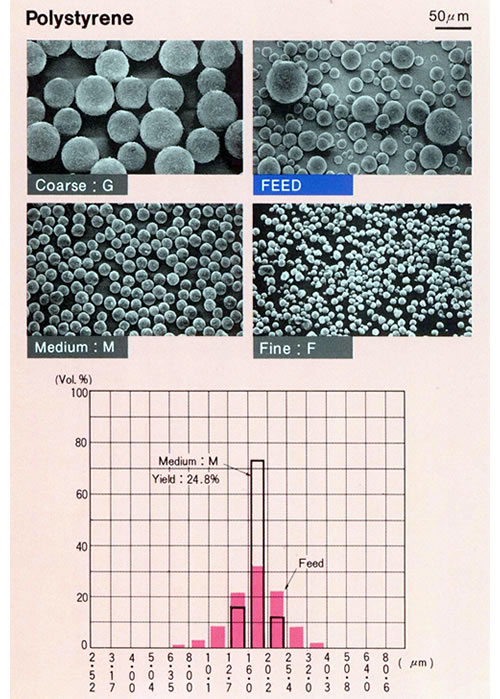

Dry process classification to three products simultaneously

Easy control of particle size distribution.

Elbow-jet is the precise air classifier for dry process, which is different from conventional classifier.

It can classify small particles to three products simultaneously, by using the original principle of Coanda Effect.

Elbow-Jet works on the principle that the trajectory of a particle in a current of air is a function of the inertia and air resistance of that particle size.

Elbow-Jet can do triple classification with simultaneous fine and coarse cuts, and can achieve sharp particle size distribution. Also, its simple structure enables easy countermeasure to abrasive.

| Number of products | Can get 3 products at one time (getting 2 products is possible) |

|---|---|

| Cut size | 0.5µm to 50µm |

| Material in contact with powder | SUS304 (Tungsten carbide is used in certain parts) |

| Model | Feed Capacity [ kg/h ] |

Total Air Flow [ m3/min ] |

Remarks |

|---|---|---|---|

| EJ-LABO | 1 - 5 | 2.0 | Automatic control (By setting up cut point) |

| EJ-PURO | 3 - 15 | 2.7 | Automatic control (For small production use) |

| EJ-05 | 10 - 70 | 4 - 6 | ↓ For production use |

| EJ-15 | 30 - 200 | 9 - 15 | |

| EJ-30 | 60 - 400 | 14 - 24 | |

| EJ-45 | 90 - 600 | 20 - 33 | |

| EJ-60 | 120 - 800 | 25 - 42 | |

| EJ-75 | 150 - 1000 | 31 - 51 | |

| EJ-90 | 180 - 1200 | 32 - 54 | |

| EJ-105 | 210 - 1400 | 41 - 69 | |

| EJ-150 | 300 - 2000 | 58 - 96 |

This classifier is very simple structure. Only putting Coanda block, two classification edges, and G block between two stainless boards.

Particles are accelerated by an ejector unit and injected into the classifier by compressed air through a feed nozzle. Its jet stream tend to flow along the curved surface of Coanda block, because of "Coanda Effect"(If there is a one side wall in a passage of jet stream, the stream flow among the wall).

Each particle injected into the classifier has a different inertia dependant on its particle size (specific gravity). The smaller particles will flow near the curved surface of Coanda block with jet stream, because of its little inertia.

On the other hand, the larger particles will fly farther from Coanda Block, aparting from jet stream, because of its big inertia. By setting two movable classification edges whose position can be set easily at outlet of streams, desired classified product can be got simultaneously.

| d50(Vol.) | -4µm(Pop.%) | +12µm(Vol.%) | |

|---|---|---|---|

| Feed material before classification | 6.36µm | 41.1% | 1.9% |

| Medium of Product | 6.28µm | 11.1% | 0.2% |

- Applications

- Toner (Pulverized Toner, Polymerized Toner, and Color Toner), Plastics, Plastic Beads (PMMA), Electric materials, Battery materials (Solder, Mn-Oxide, Ni, Li-Ni-Oxide), Abrasive materials (Cerium oxide, Al2O3, SiC)