ADM Series

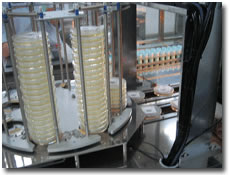

Automated dispensing/mixing device for sample and agar.

- Automates the dispensing and mixing of sample and agar.

- Ensures uniformity in both the dispensed amount and the mixing condition of the sample and the agar. Thus an operator can work consistently without variations.

- Restricts the operator's main work to setting/recovering of petri dish and sample container. Consequently the operator can work with less work load.

- Facilitates the post-incubation data administration by using a barcode label attached to the petri dish.

- Prevents contamination by installation of an optional clean booth.

| Processing capacity | 200 samples/hr (when producing petri dishes: 400 pieces/hr) |

|---|---|

| Sample dispensing accuracy | 0.1/1.0 cc ±3% |

| Agar dispensing accuracy | 16 cc ±3% |

| Maximum number of petri dishes to be stocked in the petri dish supplying section | 240 |

| Maximum number of petri dishes to be stocked in the petri dish storing section | 160 |

| Electric power source | 100V AC |

| Air | 0.5MPa Optional clean booth installable type |

| Operator | 1 |

Sample Dispensing Section

A sample dispensing robot with micro pipet moves laterally to load a chip onto each sample, and then performs the sample aspiration, sample dispensing and chip disposal.

A sample dispensing robot with micro pipet moves laterally to load a chip onto each sample, and then performs the sample aspiration, sample dispensing and chip disposal.- Uses a reader to read a barcode that is attached to a sample bottle, and then does the dispensing.

- Racks for dispensed samples are stocked in the rack storing section.

Agar Dispensing/Mixing Section

Dispenses agar onto a petri dish on which the sample has already been dispensed, and then applies a flat, circular motion to mix the sample and the agar evenly in the petri dish.

Dispenses agar onto a petri dish on which the sample has already been dispensed, and then applies a flat, circular motion to mix the sample and the agar evenly in the petri dish.- Mixing time and frequency can be set as required.

Petri Dish Supplying/Separating Section

Sets maximum of 240 petri dishes.

Sets maximum of 240 petri dishes.- Ensures trouble-free progression of a stored petri dish to the next process with its unique petri dish separating mechanism.

- Auto petri dishes are not required. There is no specification of the type of petri dish.

Barcode Sticking Section

Creates barcode information that is a combination of the sample data and the data of the dispensed amount, the operation mode etc. (In this case, the sample data is the data that has been pre-entered or read by a barcode reader.) Then, the created barcode label is sticked to the dispensed petri dish lid.

Creates barcode information that is a combination of the sample data and the data of the dispensed amount, the operation mode etc. (In this case, the sample data is the data that has been pre-entered or read by a barcode reader.) Then, the created barcode label is sticked to the dispensed petri dish lid.- Facilitates the post-incubation sample administration by the barcode.

Petri Dish Storing Section

Piles and stores a maximum of 160 dispensed petri dishes.

Piles and stores a maximum of 160 dispensed petri dishes.- The number of dishes to be piled can be set as required.

Clean Booth

There is a clean air device with a HEPA filter on the clean booth to supply clean air to the petri dish lid opening and closing section and the pipette chip.

There is a clean air device with a HEPA filter on the clean booth to supply clean air to the petri dish lid opening and closing section and the pipette chip.- There is a safety switch on the clean booth door. When the door is opened, the cycle is immediately stopped or terminated.

- Medicine inspection

- Food inspection

- Raw milk inspection

- Automated agar dispensing device

- Automated drilling and dispensing device

- Cup dropper